Urethane Casting

Visibly Perfect Short-Run PartsDevelopments in advance formula polymers (AFP’s), fiber-reinforced castings and molding methods enable our customers to quickly manufacture durable short-run production components and the highest quality prototypes with the technology and materials suitable for their project.

We offer Micro-welded inserts, EMI & RFI shielding, cast-in-color with optical color matching, in house production paint capability, Mold-Tech® finishes, and complex over-molding.

We are set apart by the caliber of our professionals. Three Cast Urethane operations in the U.S. are managed by master craftsmen combined with a talented project engineering staff to create a recipe for total customer satisfaction. We’ve delivered quality castings of up to 400 in³ with custom set-up capability to handle up to 1,000 in³. All of this with the best on-time delivery track record in the business.

- Optimal mechanical properties

- Void-free castings

- Net shape master patterns

- Micro-welded inserts

- Experts to consult with on every level

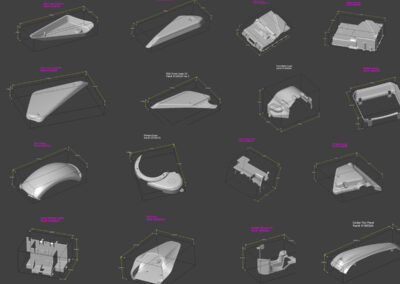

Urethane Casting Applications

- Production parts

- Alpha & Beta Builds

- Pre-Production Parts

- Functional Prototypes

- Early Revenue Generation

- A-Rank Vehicle Components

- Design & Engineering Verification

- Assembly Line Verification & Tuning

Cast Urethane Applications

Get Started Now

We've setup a file transfer system here for you to send us your project files securely. We'll contact you as soon as possible to discuss your project and service requirements.